The Importance of High-Pressure Homogenization in the Dairy Industry for Better Taste, Shelf Life, and Stability

The dairy industry is one of the most competitive and quality-driven sectors within the food processing world. Consumers demand milk, cream, yogurt, and other dairy products that not only taste good but also have a consistent texture and long shelf life. To meet these expectations, manufacturers rely on advanced processing technologies, and among these, high-pressure homogenization is one of the most essential. This process is widely adopted in dairy production lines worldwide because of its ability to improve product quality, safety, and stability. Understanding why high-pressure homogenization is important can help businesses produce better dairy products while maintaining efficiency and cost-effectiveness.

What is High-Pressure Homogenization?

High-pressure homogenization is a mechanical process used to break down and disperse fat globules in milk and dairy liquids into much smaller, uniform sizes. This is achieved by forcing the product through a narrow gap at extremely high pressures, which can range from 20 MPa to 80 MPa depending on the application. The sudden drop in pressure and turbulence causes the fat particles to break apart and evenly distribute throughout the liquid. This results in an emulsion that is stable, smooth, and resistant to separation. In dairy processing, homogenization is usually combined with pasteurization, forming a critical step in ensuring the product’s safety, texture, and shelf life.

Why Homogenization Matters in Dairy Processing

Milk in its natural state contains fat globules that vary widely in size. Without homogenization, these globules tend to rise to the surface, creating a layer of cream. While this may appeal to some traditional consumers, modern markets expect uniformity. Homogenization solves this problem by creating a consistent product with a rich taste and smooth texture. Beyond appearance, this process also impacts the way dairy products respond to heat treatment, microbial stability, and storage conditions, making it a cornerstone of modern dairy technology.

Improved Taste and Creamy Texture

Taste and texture are two of the most important factors that influence consumer choice. High-pressure homogenization significantly improves both. By breaking down large fat globules into smaller particles, the process ensures that the fat is evenly dispersed throughout the milk. This not only prevents cream separation but also gives the milk a creamier and more appealing taste. The same principle applies to cream, yogurt, and even ice cream bases. When the fat particles are small and uniform, they interact better with proteins, resulting in a smooth mouthfeel that customers associate with quality. Flavored dairy drinks also benefit, as homogenization allows flavoring agents to mix evenly, ensuring consistency in every sip.

Extended Shelf Life

One of the biggest challenges in the dairy industry is preserving freshness. Milk and dairy products are highly perishable, and any inconsistency in processing can lead to spoilage. High-pressure homogenization helps extend shelf life by creating a stable emulsion that resists separation. This stability not only improves the physical appearance of the product but also enhances the effectiveness of pasteurization or sterilization processes. Smaller fat particles allow heat to penetrate more uniformly, reducing the chances of microbial survival. As a result, homogenized dairy products can be stored for longer periods without compromising safety or taste.

Enhanced Product Stability

Stability in dairy products is not just about preventing cream from floating to the top. It also involves maintaining the product’s quality during transportation, refrigeration, and handling. Homogenization improves this stability by reducing the size of fat globules to microscopic levels, which prevents clumping and sedimentation. It also enhances the interaction between fat and protein, creating a stronger structure that holds together under different conditions. This is particularly important for yogurt and dairy-based beverages that need to remain consistent from production to consumption.

Applications in the Dairy Industry

High-pressure homogenization is not limited to milk processing. Its benefits extend to a wide range of dairy products. For example, in cream production, homogenization ensures uniform consistency and prevents fat separation. In yogurt manufacturing, it helps achieve the desired thickness and texture while improving the fermentation process. Ice cream mixes also require homogenization to create a smooth, creamy base that freezes evenly without forming large ice crystals. Cheese makers use homogenizers to standardize milk and improve the final product’s texture. The versatility of homogenization technology makes it an essential part of nearly every modern dairy production facility.

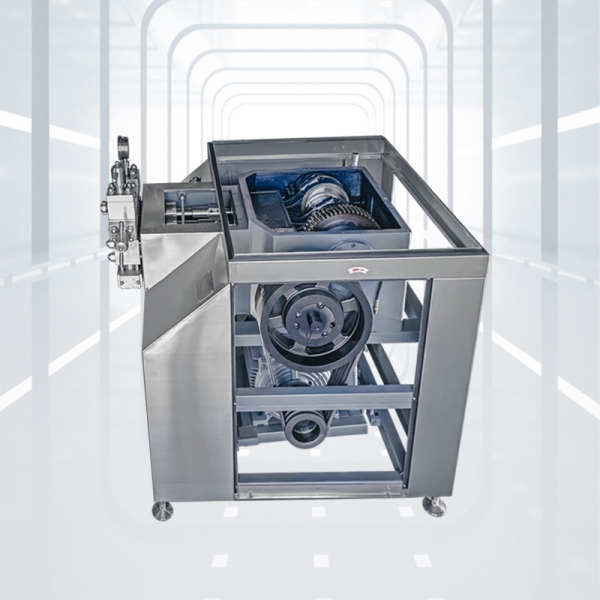

Selecting the Right Homogenizer

Choosing the right homogenizer is critical for achieving consistent results. Factors such as processing capacity, pressure range, durability, and ease of maintenance must be considered. Industrial-scale homogenizers are designed to handle thousands of liters per hour at high pressures, while smaller models cater to laboratories or pilot-scale production. Compliance with food safety and international standards, such as ISO 9001 and CE certification, is also essential for ensuring reliability and quality assurance. Leading manufacturers like Changzhou Chaoli Homogenizer Factory provide a wide range of high-pressure homogenizers suitable for dairy applications, offering both standard models and customized solutions to meet specific production needs.

Conclusion

High-pressure homogenization is a key process in modern dairy production. It ensures that milk and dairy products deliver the taste, texture, and stability that consumers expect while extending shelf life and improving processing efficiency. By adopting this technology, dairy manufacturers can maintain high product standards, reduce waste, and stay competitive in a demanding market. For companies seeking reliable homogenization solutions, investing in advanced, high-quality equipment is not just an option—it is a necessity for long-term success.