How Homogenizers Ensure Stability in Functional Beverages and Nutraceutical Drinks

The global demand for functional beverages and nutraceutical drinks has surged in recent years as consumers increasingly seek products that combine great taste with health benefits. From protein shakes and vitamin-fortified waters to plant-based drinks and probiotic beverages, these products are formulated to deliver nutrients effectively and consistently. However, one of the biggest challenges manufacturers face is maintaining stability, uniformity, and shelf life in such complex formulations. This is where homogenizers play a vital role. By breaking down and evenly dispersing particles, homogenizers ensure smooth texture, consistent taste, and stable suspensions in functional beverages, making them indispensable tools in the modern nutraceutical industry.

Unlike traditional drinks, functional beverages contain a wide range of active ingredients—proteins, vitamins, minerals, oils, plant extracts, probiotics, and more. Each ingredient has its own physical and chemical properties, which can make the final product prone to separation, sedimentation, or phase instability. For example, in protein-enriched beverages, undissolved particles may settle at the bottom, while oil-based nutrients like omega-3s tend to float or clump together. Homogenization addresses these issues by applying high pressure to uniformly reduce particle sizes and disperse all components throughout the liquid, resulting in a stable and visually appealing product.

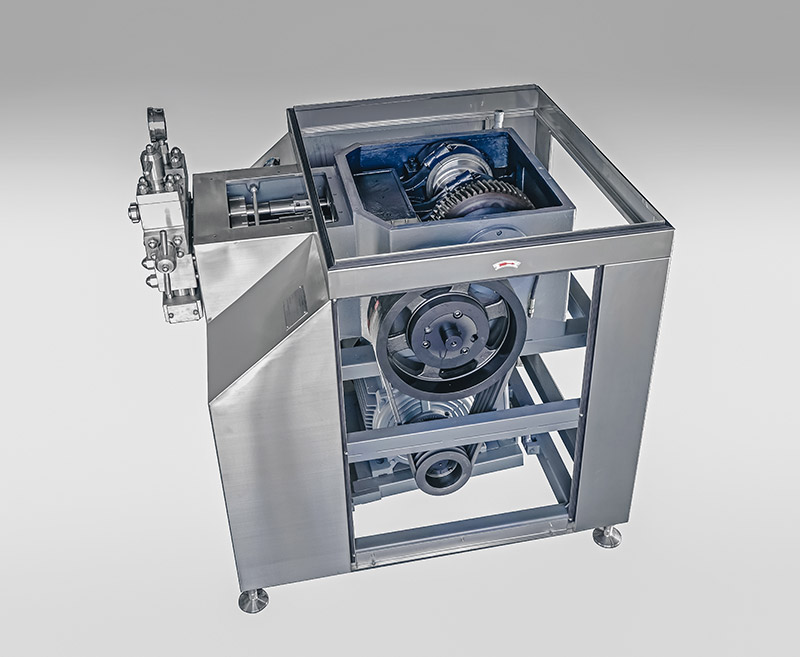

Homogenization is a mechanical process that uses high pressure to force a liquid through a narrow gap or valve, breaking down particles and droplets into smaller, uniform sizes. The smaller the particle size, the more stable the emulsion or suspension becomes. In functional beverages, this process prevents ingredient separation and enhances the bioavailability of active compounds. By reducing particle sizes to the micron or even nanometer scale, homogenization creates smooth, consistent mixtures that remain stable during storage and distribution.

A major benefit of homogenization in nutraceutical drinks is the improvement of bioavailability—the body’s ability to absorb and utilize nutrients. Many functional ingredients, such as plant extracts, fat-soluble vitamins, and omega-3 fatty acids, are poorly soluble in water. Through homogenization, these ingredients can be transformed into fine emulsions or nanoemulsions, increasing their surface area and making them easier for the body to absorb. This process not only enhances nutritional effectiveness but also allows manufacturers to deliver functional benefits in smaller, more convenient serving sizes.

Texture plays a crucial role in consumer acceptance of functional beverages. No matter how healthy or beneficial a drink is, if it feels gritty, oily, or inconsistent, consumers are unlikely to buy it again. Homogenizers eliminate such sensory problems by creating a smooth and creamy mouthfeel. In plant-based milks like soy, oat, or almond drinks, homogenization helps distribute fat particles evenly, mimicking the texture of dairy milk. Similarly, in protein shakes, it prevents clumping and improves overall drinkability, ensuring a pleasant experience from the first sip to the last.

Stability is essential for any beverage intended for commercial distribution. Without proper homogenization, functional drinks are vulnerable to phase separation, sedimentation, or spoilage over time. By producing fine, uniform dispersions, homogenizers help stabilize emulsions and suspensions, preventing separation during transportation and storage. This enhanced stability translates into longer shelf life, allowing manufacturers to expand distribution without compromising product quality. In addition, homogenization often reduces the need for artificial stabilizers or emulsifiers, aligning with the clean-label trend favored by health-conscious consumers.

Modern homogenizers are designed to balance high performance with energy efficiency, a critical factor in large-scale beverage production. Advanced designs use optimized valve geometries, intelligent pressure controls, and efficient motor systems to reduce energy consumption while maintaining precise particle size control. Automation and digital monitoring systems also allow manufacturers to fine-tune pressure levels and flow rates for different beverage formulations, ensuring consistent results while minimizing operational costs. These innovations make homogenization both environmentally responsible and economically viable.

The role of homogenization extends across a wide range of functional and nutraceutical beverages, including:

Protein and sports drinks – for improved solubility and texture.

Plant-based beverages – for fat dispersion and consistent flavor.

Probiotic drinks – for maintaining microbial stability and uniformity.

Fortified juices and waters – for preventing ingredient separation.

Omega-3 and vitamin emulsions – for enhanced absorption and clarity.

In each of these applications, homogenizers ensure that the active ingredients remain stable, effective, and appealing to consumers throughout the product’s shelf life.

Different beverages require different processing conditions. As a result, the demand for customized homogenizer solutions has grown significantly. Manufacturers like Changzhou Chaoli Homogenizer Factory offer OEM and ODM options that allow beverage producers to specify pressure ranges, material construction, and flow capacities suited to their exact formulations. For instance, a nutraceutical drink containing heat-sensitive probiotics might require lower pressures and specific cooling systems to maintain viability. Customization ensures optimal performance, energy savings, and product consistency across various beverage lines.

The future of homogenization in functional beverages lies in nanoemulsion technology and smart digital controls. Nanoemulsions, with droplet sizes below 100 nanometers, provide superior stability, clarity, and bioavailability. At the same time, smart homogenizers equipped with IoT-based sensors and automated feedback systems will enable real-time quality monitoring and process optimization. These advancements will further enhance production efficiency and product innovation in the fast-growing nutraceutical beverage market.

Homogenizers are essential for ensuring stability, consistency, and functionality in modern nutraceutical and functional beverages. By creating fine, uniform dispersions, they enhance nutrient bioavailability, improve texture, and extend shelf life—all while supporting clean-label and energy-efficient production goals. As consumer demand for health-focused drinks continues to rise, advanced homogenization technologies will remain at the heart of product innovation and quality assurance. Through precision engineering and customization, manufacturers like Changzhou Chaoli Homogenizer Factory continue to drive progress in beverage processing, enabling companies to deliver superior products that meet both consumer expectations and industry standards.