The Use of High-Pressure Homogenizers in Chemical Emulsions and Dispersions

High-pressure homogenizers have become an essential part of the modern chemical industry, where precision, consistency, and product stability are key to success. Many chemical formulations—such as paints, coatings, adhesives, lubricants, and emulsions—depend on achieving uniform particle size and stable dispersions. Traditional mixing methods often fail to produce the fine, consistent mixtures required for optimal product performance. High-pressure homogenization, however, offers a powerful solution by applying intense mechanical forces that create stable emulsions and dispersions with exceptional uniformity and quality.

In the field of chemical processing, emulsions and dispersions play a critical role in product formulation. An emulsion is a mixture of two immiscible liquids, such as oil and water, where one liquid is finely distributed within the other. This is common in products like emulsified fuels, coatings, and cutting fluids. A dispersion, by contrast, involves solid particles evenly suspended in a liquid medium, such as pigments in paints or fillers in adhesives. Without adequate particle size reduction and distribution, these mixtures tend to separate over time, causing inconsistent texture, appearance, or performance. Homogenizers are specifically designed to overcome this challenge by breaking down particles into microscopic or nanoscopic sizes.

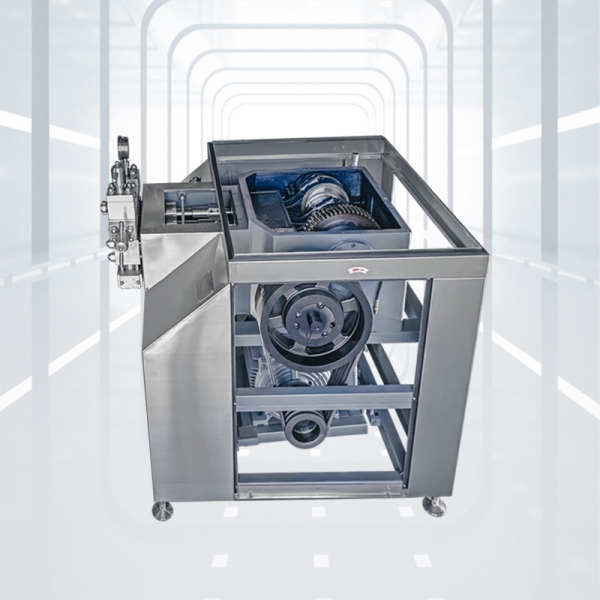

High-pressure homogenization works by forcing a fluid through a narrow orifice at extremely high pressure—ranging from 50 to over 1500 bar—creating turbulence, shear, and cavitation forces that break particles and droplets apart. The result is a fine, uniform dispersion or emulsion with improved stability. By adjusting the operating pressure and flow rate, manufacturers can precisely control the final particle size distribution, ensuring that every batch meets strict quality standards. This process makes it possible to produce advanced chemical products with consistent physical properties and extended shelf life.

The benefits of using high-pressure homogenizers in the chemical industry are extensive. The primary advantage is superior uniformity, as homogenization achieves submicron or nanometer-sized particles that produce stable mixtures. This not only improves the consistency of the final product but also enhances visual and physical properties such as color, gloss, viscosity, and smoothness. Homogenization also extends product stability by preventing separation, sedimentation, and agglomeration. From an operational standpoint, it is often more energy-efficient and reliable than traditional mixing or milling systems. Modern homogenizers are designed for continuous, large-scale use while maintaining consistent output quality.

High-pressure homogenizers find applications across a wide range of chemical processes. In paints and coatings, they ensure even pigment dispersion and vibrant, long-lasting colors. In adhesives and sealants, they provide uniform filler distribution for stronger bonding and better performance. Lubricants and greases rely on homogenization to maintain consistent oil-water emulsions under extreme conditions, preventing separation and improving lubrication properties. In polymer production, homogenizers are used to create stable latex and resin emulsions that enhance flexibility and film formation. They are also instrumental in the production of nanomaterials, catalysts, and specialty chemicals, where uniform particle size and dispersion quality directly influence product functionality.

Particle size reduction is the key to achieving long-term stability in emulsions and dispersions. Smaller particles exhibit slower sedimentation rates and greater resistance to phase separation. In emulsions, fine droplets prevent coalescence between the oil and water phases, while in dispersions, uniformly distributed solid particles reduce the risk of settling or clumping. High-pressure homogenization enables manufacturers to achieve these fine particle sizes consistently, resulting in stable formulations that maintain their performance and appearance over extended storage periods.

While the homogenization process involves high mechanical energy, today’s equipment emphasizes energy efficiency and process optimization. New designs incorporate advanced valve geometries, efficient pumping systems, and smart pressure controls that minimize energy consumption without compromising performance. Some systems even include heat recovery features that reuse the energy generated during processing. Automated control systems allow operators to precisely monitor parameters such as pressure, temperature, and flow, optimizing performance and reducing operational costs. These innovations make homogenization a sustainable and cost-effective solution for large-scale chemical manufacturing.

Customization plays an important role in meeting the specific demands of chemical processing. Every formulation has unique physical and chemical characteristics, so homogenizers must be tailored to handle different viscosities, corrosive substances, or particle types. Manufacturers such as Changzhou Chaoli Homogenizer Factory offer OEM and ODM solutions that customize pressure levels, valve structures, and material selections for each application. For example, homogenizers designed for corrosive dispersions may use high-grade stainless steel or ceramic materials to ensure durability and product purity. This customization ensures reliable operation, long service life, and compliance with industry standards.

The integration of homogenizers with modern digital and automated systems is another emerging trend in chemical production. IoT-enabled sensors and smart controls allow real-time monitoring of operating conditions, while predictive maintenance systems can detect early signs of wear or inefficiency. This digital connectivity enhances process reliability, minimizes downtime, and aligns with Industry 4.0 initiatives that promote intelligent, data-driven manufacturing. As a result, companies can maintain higher efficiency and consistency while reducing operational risks.

Looking ahead, the future of homogenizer technology in the chemical sector lies in nanotechnology and advanced dispersion systems. As industries increasingly rely on nanomaterials and high-performance coatings, the ability to produce stable nanoemulsions and nanodispersions will become essential. Next-generation high-pressure homogenizers will feature improved flow dynamics, better cavitation control, and enhanced precision for producing ultra-fine particles with less energy. These innovations will expand the potential of homogenization into new areas of advanced materials, energy storage, and sustainable chemical manufacturing.

In conclusion, high-pressure homogenizers are vital to the chemical industry’s ongoing pursuit of stability, uniformity, and innovation. Their ability to produce finely dispersed and emulsified mixtures improves product performance, appearance, and shelf life across a broad spectrum of applications. As technology advances, energy efficiency, digital integration, and nano-level processing will continue to redefine what homogenizers can achieve. Manufacturers like Changzhou Chaoli Homogenizer Factory are leading this transformation, providing customized, high-performance solutions that support the evolving needs of chemical production worldwide.