How Homogenizers Improve Lubricants and Industrial Fluids

Homogenizers play an increasingly vital role in the production of lubricants and industrial fluids, ensuring consistency, performance, and long-term stability across a wide range of applications. In industries where mechanical systems operate under high pressure, extreme temperature, and heavy load, the quality of lubricants determines both efficiency and equipment lifespan. A stable, well-dispersed lubricant helps reduce friction, minimize wear, and prevent component failure. However, producing high-performance lubricants is not as simple as mixing oils and additives together—it requires precise dispersion and emulsification, which is where homogenization technology becomes essential.

In the manufacturing of lubricants, achieving a uniform mixture of base oils, additives, and performance-enhancing agents is critical. Lubricants often contain various components such as viscosity modifiers, anti-wear agents, corrosion inhibitors, detergents, and dispersants. These ingredients must be evenly distributed throughout the formulation to perform effectively. Without proper homogenization, additives can separate or settle over time, leading to inconsistent lubrication, reduced protection, and shorter service life. By applying high pressure and mechanical shear, homogenizers ensure complete dispersion and integration of all ingredients, resulting in a stable and high-quality lubricant.

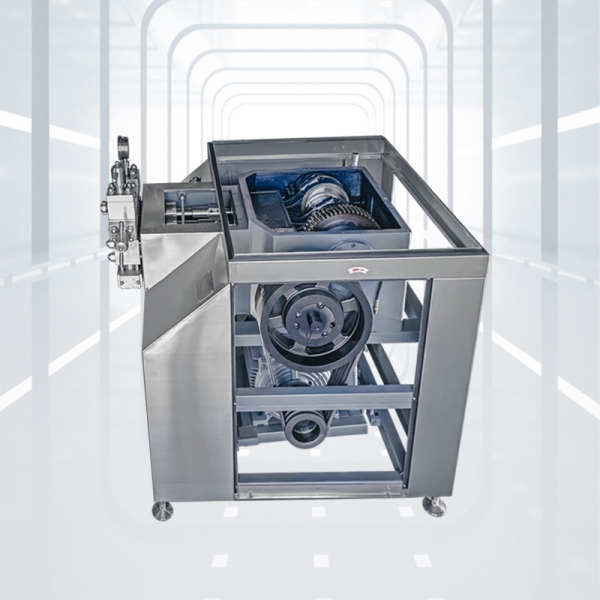

The homogenization process works by forcing the lubricant mixture through a narrow valve at extremely high pressure. This creates intense turbulence, shear, and cavitation forces that break down particles and droplets into uniform, microscopic sizes. The result is a finely dispersed, homogeneous fluid with consistent properties throughout the batch. Unlike simple mixers or agitators, which only blend materials on a macro scale, homogenizers act on a microstructural level. This not only improves stability but also enhances the performance of lubricants in demanding industrial environments such as automotive engines, hydraulic systems, and heavy machinery.

One of the key benefits of using homogenizers in lubricant production is improved dispersion of solid and liquid additives. Many additives, such as molybdenum disulfide, graphite, or zinc-based compounds, are solid particles that enhance wear resistance and load-bearing capacity. These materials tend to agglomerate or settle when not properly dispersed. Homogenization ensures that these particles are evenly distributed and remain suspended in the base oil, maintaining consistent performance during storage and use. Similarly, emulsified lubricants—used in metalworking fluids and cutting oils—require the stable mixing of oil and water phases, which homogenizers can achieve with exceptional precision.

Another major advantage of homogenization is the enhancement of lubricant stability over time. Inconsistent or poorly mixed formulations can separate, oxidize, or degrade under temperature fluctuations and long-term storage. By producing uniform particle sizes and stable dispersions, homogenizers extend the shelf life and reliability of lubricants. This results in reduced maintenance costs and fewer product failures for both manufacturers and end users. For industrial fluids such as coolants, heat transfer oils, and hydraulic fluids, stability is particularly important since phase separation or particle settling can compromise system performance and cause costly equipment damage.

In addition to improving stability, homogenization also enhances the physical and chemical properties of lubricants. Uniformly dispersed additives improve the oil’s load-carrying capacity, thermal stability, and oxidation resistance. The consistent molecular structure also enhances viscosity control and film strength, ensuring smoother operation under varying conditions. In metalworking fluids, fine emulsions created through homogenization improve cooling efficiency and surface finish while reducing tool wear. These improvements directly translate into better productivity, longer machine life, and higher energy efficiency across manufacturing operations.

Modern high-pressure homogenizers are also designed with energy efficiency and process optimization in mind. Traditional mixing systems often consume large amounts of energy without achieving the same degree of dispersion. By contrast, homogenizers use optimized flow channels, advanced valve designs, and precise pressure control to achieve superior results with less energy input. Automation and digital control systems further enhance process accuracy, allowing manufacturers to adjust operating conditions in real time for different lubricant formulations. These advancements make homogenization both cost-effective and environmentally sustainable, aligning with the global push toward cleaner production.

Customization has become an important factor in lubricant and industrial fluid processing. Different formulations require different levels of pressure, temperature, and flow control, depending on the viscosity and composition of the mixture. Manufacturers such as Changzhou Chaoli Homogenizer Factory offer customized homogenization solutions (OEM and ODM) tailored to meet the specific requirements of each application. For example, high-viscosity greases may need reinforced pumps and special sealing systems, while water-based lubricants require corrosion-resistant materials. By providing these tailored designs, homogenizer manufacturers help customers achieve optimal results and reliable long-term performance.

Homogenizers also play an essential role in the development of next-generation lubricants, including synthetic and bio-based formulations. As industries transition toward environmentally friendly products, bio-lubricants made from vegetable oils are gaining popularity. However, these natural oils present challenges in stability and oxidation resistance. Homogenization helps improve the dispersion of antioxidants and stabilizers in bio-lubricants, enhancing their performance and shelf life. Similarly, in nanotechnology applications, homogenizers are used to create nano-dispersions of solid lubricants that reduce friction at the molecular level, opening new possibilities for high-performance industrial fluids.

As technology evolves, the future of homogenization in lubricant manufacturing will focus on nanoemulsion and smart process control. Nanoemulsions, with droplet sizes below 100 nanometers, offer superior stability, transparency, and enhanced additive efficiency. At the same time, smart homogenizers equipped with IoT sensors and automated feedback systems will enable real-time monitoring and predictive maintenance. This digital integration will ensure consistent quality, minimize downtime, and reduce energy consumption across large-scale production lines.

In conclusion, homogenizers have become indispensable in the formulation and production of lubricants and industrial fluids. They provide precise control over particle size, enhance stability, and improve the overall performance of complex mixtures. By ensuring uniform dispersion of additives and preventing separation, homogenizers contribute to longer-lasting, more efficient, and more sustainable lubrication systems. As industries continue to demand higher standards of performance and environmental responsibility, advanced homogenization technologies—such as those developed by Changzhou Chaoli Homogenizer Factory—will remain at the forefront of innovation, driving the next generation of high-quality lubricants and industrial fluids.