Improving the Quality and Performance of Lubricants with Homogenizers

Lubricants are critical for reducing friction, minimizing wear, and ensuring smooth operation in a wide variety of industrial applications. They play a vital role in machinery ranging from automotive engines to heavy industrial equipment, where the performance and longevity of components depend heavily on the quality and consistency of the lubricant. To achieve the required level of performance, lubricants must be carefully formulated with a range of additives—such as anti-wear agents, corrosion inhibitors, dispersants, and viscosity modifiers. However, ensuring that these additives are evenly distributed throughout the lubricant is a challenge. This is where high-pressure homogenizers come into play, offering an advanced solution to improve the quality and performance of lubricants.

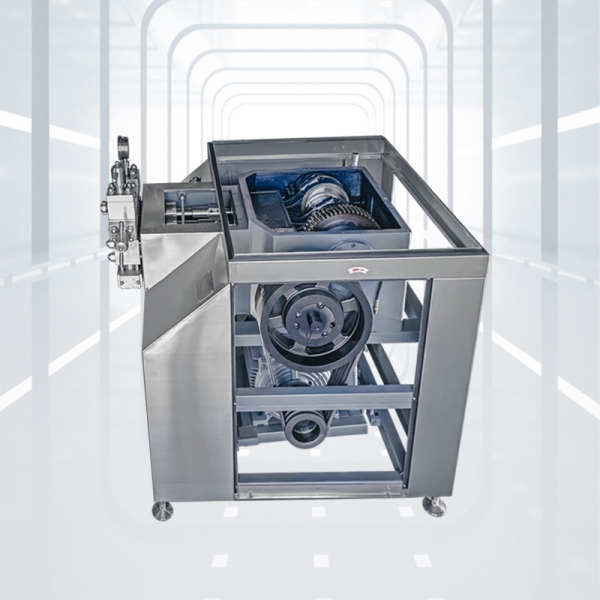

High-pressure homogenizers are designed to apply intense mechanical forces to fluid mixtures, breaking down particles and droplets into a uniform, microscopic size. By passing the lubricant mixture through a narrow valve under extreme pressure, homogenizers generate shear forces that ensure the even dispersion of additives and base oils. The resulting mixture is highly stable, with a uniform consistency that prevents the separation or settling of ingredients over time. This uniformity enhances the overall performance of lubricants, improving their effectiveness in reducing friction and wear during use.

One of the main benefits of using homogenizers in lubricant production is the improvement in the dispersion of solid additives. Many lubricants include solid particles such as molybdenum disulfide, graphite, or zinc-based compounds that enhance wear resistance and load-carrying capacity. These particles must be uniformly dispersed throughout the lubricant to achieve maximum performance. Without proper dispersion, the additives can agglomerate or settle, reducing their effectiveness and potentially damaging machinery. Homogenizers ensure that these solid particles are evenly distributed, helping lubricants maintain their performance throughout their lifecycle.

In addition to solid additives, homogenizers also improve the emulsification of oil and water-based components in lubricants. Water-based lubricants, such as cutting fluids and metalworking oils, often require the stable blending of water and oil phases. Homogenization helps achieve a finer and more stable emulsion, ensuring the lubricant remains effective during use. It also prevents phase separation, which can occur when water and oil separate over time, reducing the efficiency of the lubricant and increasing the risk of corrosion and wear in machinery.

The stability of lubricants is one of the most important factors influencing their performance. Homogenizers play a significant role in extending the shelf life of lubricants by preventing the settling or separation of ingredients. In traditional mixing processes, some additives can settle or clump together, leading to an inconsistent product. High-pressure homogenizers ensure a finer, more uniform particle size, preventing separation and enhancing the lubricant's ability to maintain consistent performance even after extended periods of storage. As a result, manufacturers can deliver high-quality lubricants that provide stable and reliable performance over time.

In addition to improving stability, homogenization also enhances the physical properties of lubricants. The uniform particle distribution achieved through homogenization improves the overall texture, appearance, and viscosity of lubricants, ensuring smoother application and better coverage on machinery surfaces. Uniform viscosity across the entire lubricant helps reduce friction more effectively, leading to lower temperatures and reduced wear on moving parts. This, in turn, extends the life of the machinery and reduces the need for maintenance or frequent oil changes.

The impact of homogenizers on lubricant performance is particularly evident in industrial applications where extreme conditions, such as high temperatures, heavy loads, and high speeds, are common. High-performance lubricants used in automotive engines, hydraulic systems, and heavy machinery must be able to maintain their properties under these demanding conditions. Homogenization ensures that the lubricant can withstand high pressures and temperatures without breaking down or losing its effectiveness. By ensuring the even distribution of all components, homogenizers help lubricants maintain their protective properties throughout their lifecycle, reducing the risk of component failure.

Moreover, energy efficiency is another area where homogenization brings significant benefits. Traditional mixing methods, such as paddle mixers and stirrers, often consume a large amount of energy without achieving the same level of uniformity as homogenizers. High-pressure homogenizers, on the other hand, are designed to be highly energy-efficient while still achieving superior particle dispersion and emulsification. This efficiency not only reduces operational costs but also aligns with the growing demand for sustainable and environmentally friendly manufacturing practices.

The customization of homogenization processes is another important factor in improving lubricant quality. Different types of lubricants require different levels of pressure, flow rate, and temperature for optimal performance. Manufacturers like Changzhou Chaoli Homogenizer Factory offer OEM and ODM solutions that can be tailored to meet the specific needs of each lubricant formulation. Whether producing low-viscosity oils, high-viscosity greases, or specialty lubricants for extreme conditions, homogenizers can be configured to deliver the exact particle size and dispersion characteristics required.

Looking to the future, innovations in nanoemulsion technology and smart process control will likely drive the next wave of improvements in lubricant performance. Nanotechnology has the potential to enhance lubricant properties by incorporating nanoparticles that reduce friction at the molecular level. High-pressure homogenizers are already being used to create these advanced formulations, and future developments will likely make it easier to produce even smaller, more effective nanoparticles. Additionally, the integration of smart sensors and automated control systems will allow for real-time monitoring and adjustment of the homogenization process, further improving efficiency and consistency.

In conclusion, high-pressure homogenizers are a critical tool in improving the quality, performance, and stability of lubricants. By ensuring uniform particle size distribution and preventing phase separation, homogenization enhances the effectiveness of lubricants in reducing friction, wear, and corrosion. The benefits of homogenization extend across a wide range of industrial applications, from automotive engines to heavy machinery, and contribute to longer-lasting, more reliable lubricants. As technology continues to evolve, the role of homogenizers in lubricant manufacturing will only grow, providing a key solution to the increasing demand for high-performance, energy-efficient, and sustainable industrial fluids.