How Chaoli Homogenizers Help Scale Up Your Production Process

Scaling up from laboratory trials to full industrial production can be a daunting step for any manufacturer. Processes that work efficiently in small batches often become more complex when flow rates rise, pressures increase, and quality must remain consistent. This is where Chaoli Homogenizer Factory provides a powerful advantage. With decades of engineering experience and advanced high-pressure technology, Chaoli homogenizers ensure that scaling up your operation happens smoothly, reliably, and economically. At the core of scaling success is consistency. Whether you are producing food beverages, cosmetics, pharmaceuticals, biologics, or nano-materials, the final product must look and perform the same at any batch size. Chaoli homogenizers apply controlled high pressure to reduce particle sizes uniformly, stabilize emulsions, and ensure balanced dispersion of ingredients. This consistency allows manufacturers to replicate laboratory results at industrial scale without sacrificing quality.

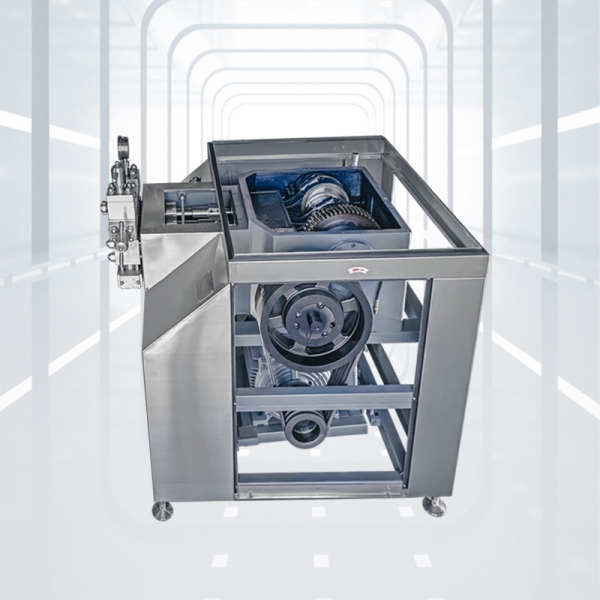

Production efficiency becomes increasingly important as volumes grow. Chaoli’s homogenizer models—ranging from compact machines like the 3011 and 3015 to high-capacity units such as the 3090 and 4110—are designed to deliver stable continuous operation. High flow output, optimized pressure systems, and precision mechanical structure ensure that your process runs smoothly during long production shifts. This means fewer bottlenecks on the factory floor and a higher overall production capacity. Reliability and durability are key factors for successful large-scale manufacturing. Equipment used in industrial settings must withstand prolonged operation, variable materials, and demanding environments. Chaoli homogenizers are built with wear-resistant components and reinforced structures to ensure long service life. Critical parts are engineered to minimize mechanical stress and reduce maintenance downtime. This durability lowers operational costs and keeps production running uninterrupted.

A smooth transition from pilot testing to mass production also requires scalability in process control. Chaoli homogenizers maintain accurate pressure control and repeatable performance across different batch sizes. Manufacturers can fine-tune processing parameters such as flow rate, product viscosity, and particle reduction levels, ensuring that the same technical outcome achieved in experimental stages can be reproduced in commercial-scale operations. Another major advantage of Chaoli homogenizers is their flexibility across industries and applications. Whether a company is scaling up dairy beverages, pharmaceutical suspensions, cosmetic emulsions, or nano-particle dispersions, Chaoli provides a solution that adapts to diverse production needs. This versatility helps companies expand product lines or enter new markets without changing core processing equipment.

Finally, scaling up isn’t just about mechanical performance—it is also about support. Chaoli Homogenizer Factory offers customers professional guidance throughout their journey: selecting a suitable model, designing process setups, optimizing operating parameters, and ensuring after-sales service. This partnership approach makes the scale-up process faster, easier, and more successful. From laboratory innovation to mass-market execution, Chaoli homogenizers provide the power, consistency, and efficiency required to scale production with confidence. With proven engineering, advanced pressure performance, and long-term reliability, Chaoli ensures that growing your business also means growing your quality.