Achieving Perfectly Smooth and Stable Formulations in the Cosmetics Industry with Chaoli Technology

In the cosmetics industry, product quality is defined not only by the effectiveness of active ingredients but also by texture, appearance, and long-term stability. Consumers expect creams, lotions, serums, and emulsions to feel smooth on the skin, look uniform, and maintain their performance throughout their shelf life. Achieving this level of quality requires advanced processing technology, and high-pressure homogenization has become a key solution. Chaoli Homogenizer Factory provides reliable homogenization technology that helps cosmetic manufacturers achieve perfectly smooth and stable formulations. Cosmetic formulations often consist of complex mixtures of oils, water, waxes, and active ingredients. Without proper homogenization, these components can separate, leading to uneven texture, reduced effectiveness, and poor consumer experience. Chaoli homogenizers apply controlled high pressure to break down droplets and particles into fine, evenly distributed sizes. This process creates stable emulsions that resist separation and maintain a consistent appearance, even under varying storage and temperature conditions.

Texture and skin feel are critical factors in cosmetic product success. Fine particle size achieved through homogenization results in a silky, smooth consistency that enhances application and absorption. Whether producing moisturizing creams, sunscreens, or anti-aging serums, Chaoli technology ensures uniform dispersion of ingredients, allowing products to spread evenly and deliver active components effectively to the skin. Stability is another major challenge in cosmetic manufacturing. Products must remain consistent over long periods without changes in color, viscosity, or performance. High-pressure homogenization significantly improves formulation stability by strengthening the emulsion structure and reducing the likelihood of creaming or sedimentation. Chaoli homogenizers provide stable pressure and sufficient flow, ensuring repeatable results batch after batch and supporting reliable long-term product quality.

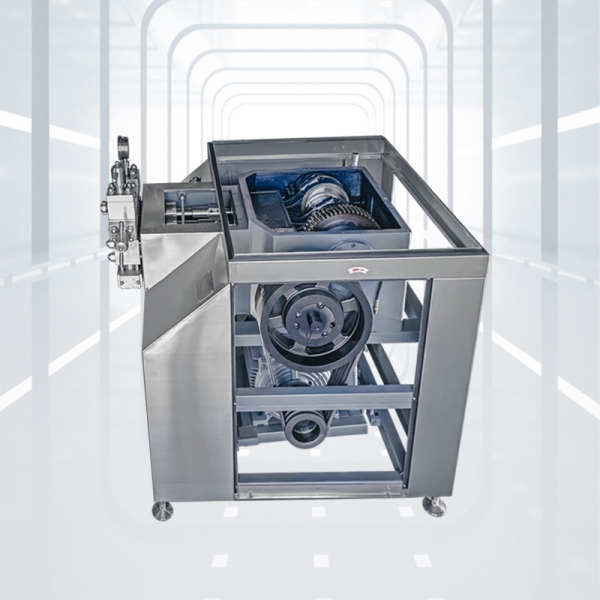

Efficiency and scalability are also essential for cosmetic producers operating in competitive global markets. From small-scale R&D and pilot testing to full industrial production, Chaoli offers homogenizer models that support seamless scale-up. Manufacturers can develop formulations in the laboratory and confidently transition them to mass production without compromising texture or stability. The durability and long service life of Chaoli equipment further reduce downtime and maintenance costs. In addition to performance, modern cosmetic manufacturing places increasing emphasis on sustainability and process efficiency. Chaoli homogenizers are engineered for optimized energy use and low noise operation, contributing to a safer and more environmentally responsible production environment. Their robust design ensures consistent operation even during continuous production runs, supporting efficient manufacturing workflows.

With decades of experience and a deep understanding of homogenization technology, Chaoli Homogenizer Factory continues to support cosmetic manufacturers worldwide. By delivering smooth textures, stable emulsions, and reliable performance, Chaoli technology helps brands create high-quality cosmetic products that meet consumer expectations and stand out in the market.