From Laboratory to Industry: Scaling Up with Chaoli Homogenizers

Scaling a process from laboratory research to full industrial production is one of the most challenging transitions manufacturers face. What works perfectly in a small test environment often becomes complex when volumes increase and consistency becomes critical. At Chaoli Homogenizer Factory, we design high-pressure homogenization systems that bridge this gap smoothly, ensuring that product performance in the lab can be replicated reliably on the production floor. In laboratory settings, scientists and engineers depend on precise control, stable pressure, and repeatable results. These factors are equally essential when processes scale up. Chaoli’s homogenizers—ranging from models 3011 and 3015 to high-capacity units like 3090 and 4110—are engineered to maintain the same particle size reduction, dispersion quality, and stability achieved in benchtop trials. This seamless transition allows companies to develop products with confidence, knowing their research outcomes can withstand industrial scaling.

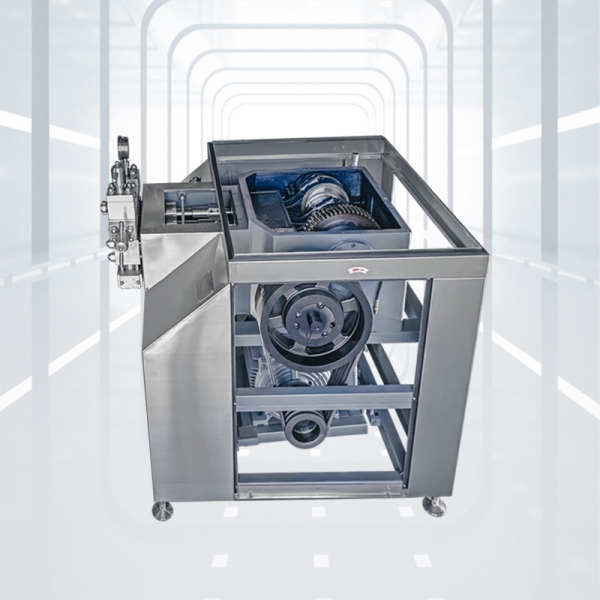

One of the common challenges during scale-up is maintaining uniformity and quality across larger batches. Variations in viscosity, temperature, and flow rate can influence the final product. Our homogenizers deliver sufficient flow, consistent high pressure, and optimized energy efficiency to ensure that raw materials are processed uniformly, no matter the volume. This consistency is particularly important for industries such as dairy, beverages, pharmaceuticals, cosmetics, and nano-material production. Another key factor in successful scale-up is equipment durability and long-term reliability. Industrial production runs for long hours and often requires systems that can handle continuous, rigorous operation. Chaoli homogenizers are built with high-strength materials, precise mechanical structures, and extended-life wear parts. These features guarantee long service life while minimizing downtime, maintenance, and operational noise—enhancing overall production efficiency.

Scaling up also means adapting to growing production demands without compromising quality. Our advanced homogenization technology allows manufacturers to fine-tune parameters and achieve the same micro-level effects seen in laboratory trials. Whether the goal is emulsification, cell disruption, particle size reduction, or material modification, Chaoli provides stable performance and advanced control capabilities to meet evolving industrial requirements. In today’s competitive market, the ability to scale quickly and efficiently can determine the success of new product development. Chaoli Homogenizer Factory supports customers through every stage—from R&D experiments to pilot production and finally to large-scale manufacturing. With decades of technical expertise and a commitment to quality, we ensure that scaling up does not mean sacrificing precision or performance.

From laboratory innovations to fully industrialized processes, Chaoli homogenizers empower manufacturers to grow with confidence. By combining advanced engineering, reliable operation, and tailored solutions, we enable companies across various sectors to turn scientific ideas into commercially successful products.