Future Trends in Homogenizer Technology Across Non-Dairy Industries

Homogenizers have long been a cornerstone of industrial processing, traditionally known for their role in the dairy sector. However, in recent years, the application of homogenization has expanded far beyond milk and cream production. Today, industries such as pharmaceuticals, biotechnology, cosmetics, food and beverages, and chemicals all rely on homogenizers to achieve product uniformity, texture, and stability. As technological innovation accelerates, the future of homogenizer technology in non-dairy industries is being reshaped by new materials, automation, energy efficiency, and digital integration. These advancements are setting new standards for productivity, sustainability, and precision across multiple fields.

Non-dairy industries depend on homogenization to ensure consistent quality and performance in products that range from cosmetic creams to pharmaceutical suspensions. In the food sector, homogenizers stabilize sauces, juices, and plant-based beverages. In pharmaceuticals, they create nanoemulsions and drug delivery systems, while in cosmetics, they ensure smooth, stable emulsions for lotions and serums. Chemical and biotechnology industries use homogenization to disperse pigments, emulsify lubricants, and break down cells for protein extraction. As these industries continue to diversify, homogenizer technology must evolve to meet increasingly complex processing demands.

One of the most significant future trends in homogenizer technology is digitalization. Modern homogenizers are moving toward full automation with IoT-enabled control systems, allowing real-time monitoring of pressure, temperature, and flow rate. Through smart sensors and data analytics, operators can optimize performance, reduce downtime, and ensure consistent quality. Predictive maintenance—powered by artificial intelligence—can detect wear and tear before it leads to failure, reducing maintenance costs and production interruptions. These digital advancements also enable remote operation and integration into broader smart factory networks, improving overall plant efficiency.

As industries focus on environmental responsibility, energy-efficient homogenization has become a key area of innovation. Traditional homogenization consumes large amounts of power, especially in continuous, high-pressure applications. New designs now feature optimized flow paths, advanced valve geometries, and improved motor efficiency to minimize energy consumption. Some systems recover and reuse heat generated during the homogenization process, further enhancing sustainability. Manufacturers are also developing machines that operate effectively at lower pressures while achieving the same particle size reduction, helping companies cut both energy costs and carbon emissions.

The demand for ultra-fine emulsions and suspensions is growing rapidly, especially in the pharmaceutical, cosmetic, and food supplement industries. This has led to the development of nano-level homogenization technology, which can achieve particle sizes below 100 nanometers. These ultra-fine dispersions improve bioavailability in pharmaceuticals, enhance texture and stability in cosmetics, and create new possibilities for functional foods. Future homogenizers will feature more precise pressure control and micro-channel flow systems that allow for highly controlled nanoemulsion production. This level of precision marks a major step toward next-generation processing capabilities.

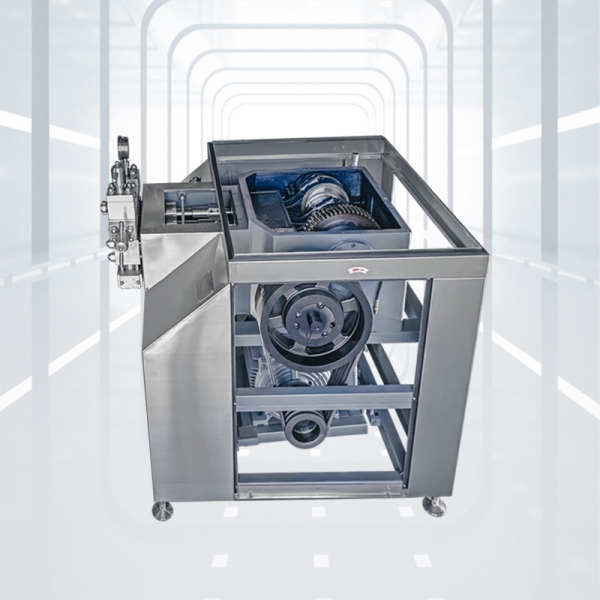

Every industry has distinct requirements, and future homogenizer technology is expected to focus heavily on customized OEM and ODM designs. Rather than one-size-fits-all equipment, companies now seek machines tailored to their specific processes, materials, and output needs. For example, a cosmetic manufacturer may need a homogenizer with special seals for viscous materials, while a pharmaceutical company may require sanitary-grade stainless steel construction with high pressure capabilities. Manufacturers such as Changzhou Chaoli Homogenizer Factory are leading the way by offering bespoke solutions that combine performance, efficiency, and compliance with international standards.

As homogenizers are used across various industries, the materials used in their construction must meet different chemical and physical requirements. Future homogenizers will feature advanced materials such as wear-resistant ceramics, high-grade stainless steel, and corrosion-resistant coatings. These materials not only enhance durability but also reduce maintenance frequency and ensure contamination-free processing. In industries like pharmaceuticals and chemicals, such improvements are vital for maintaining product integrity and meeting regulatory requirements.

Sustainability is influencing every aspect of manufacturing, and homogenizer technology is no exception. Future designs are expected to incorporate closed-loop systems that minimize waste, reduce water usage, and optimize energy recovery. Additionally, modular homogenizers that can be easily reconfigured for multiple applications will support flexible manufacturing, reducing the need for additional machinery. These innovations align with global sustainability goals and help companies move toward greener, more efficient production systems.

As research and development play a critical role in innovation, the ability to scale homogenization processes from the lab to full production is becoming increasingly important. Future homogenizers will offer seamless scalability, ensuring that the parameters optimized in a laboratory setting can be replicated exactly in industrial equipment. This consistency shortens development cycles and accelerates product launches in industries such as pharmaceuticals, biotechnology, and specialty chemicals.

With greater automation and operational complexity, safety remains a top priority. Future homogenizers will include enhanced safety features such as automatic pressure relief, intelligent shutdown systems, and improved ergonomic designs for easier maintenance. User-friendly touch-screen interfaces and digital dashboards will simplify control and data management. These improvements not only protect operators but also ensure smoother and more reliable production.

The future of homogenizer technology across non-dairy industries is defined by innovation, efficiency, and precision. Digital integration, energy efficiency, nanotechnology, and customized design are reshaping how homogenizers operate and perform. From pharmaceutical nanoemulsions to cosmetic formulations and chemical dispersions, these advancements will deliver higher quality, lower costs, and improved sustainability. Manufacturers like Changzhou Chaoli Homogenizer Factory are at the forefront of this evolution, combining expertise, customization, and advanced engineering to meet the changing needs of global industries. As technology continues to advance, homogenizers will remain a critical component in driving the next generation of high-performance, sustainable manufacturing.