How Chaoli Technology is Improving Beverage Quality Across the Globe

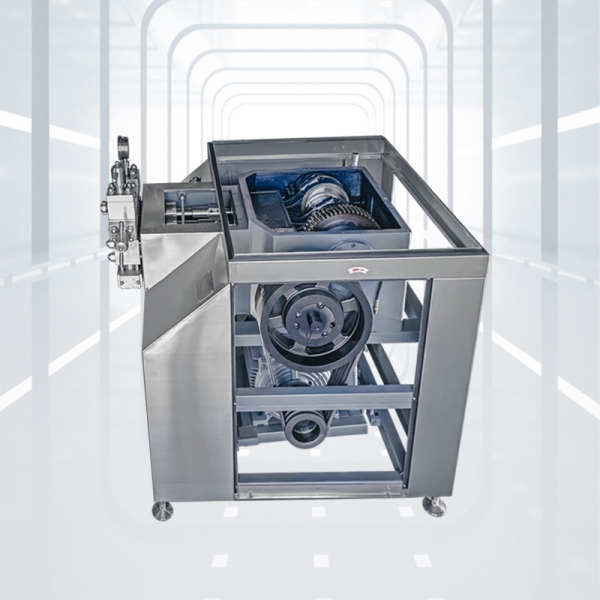

In the global beverage industry, consistency, smooth texture, and long-term stability are essential for building strong brands and winning consumer trust. From dairy drinks and juices to plant-based beverages and functional nutrition products, manufacturers rely heavily on advanced processing technology to deliver quality. Chaoli Homogenizer Factory has become a trusted partner worldwide by providing high-pressure homogenization solutions that elevate beverage quality while supporting efficient, large-scale production. The core principle behind beverage homogenization is the reduction of particle size to create stable, uniform mixtures. Whether dealing with fats, fibers, proteins, or suspended solids, our high-pressure homogenizers break them down into fine, evenly distributed particles. This ensures a smoother mouthfeel, brighter appearance, and improved flavor release—key attributes that directly impact consumer satisfaction. Chaoli’s models, such as the 3011, 3030, and 3090, are engineered to achieve these effects with exceptional precision and consistency.

Beyond texture improvement, stability is a major concern for beverage manufacturers. Without proper homogenization, products are prone to separation, sedimentation, or creaming during storage and transport. Chaoli technology helps prevent these issues by creating micro- and nano-level dispersion that enhances the stability of emulsions and suspensions. This technology plays an especially important role in functional drinks, where added vitamins, proteins, or plant extracts must remain evenly distributed throughout the product’s shelf life. Another advantage Chaoli brings to global beverage producers is operational efficiency. Our homogenizers are designed for reliable high-pressure performance, long service life of wearing parts, and low noise during operation. This allows beverage factories to run continuous production with minimal downtime. The robust design and optimized flow rates of models like the 3045 and 4110 help manufacturers keep up with rising market demand while maintaining product quality at every batch.

Energy savings and sustainability have also become priorities in modern beverage processing. Chaoli’s homogenizers are built with advanced mechanical structures and precise engineering that reduce unnecessary energy consumption. By improving processing efficiency, beverage companies can achieve high-quality results with lower operational costs—supporting greener and more sustainable production practices. In addition to technology, Chaoli provides comprehensive support for customers at every stage of their production journey. From R&D trials and pilot testing to full-scale implementation, our team of experts assists beverage manufacturers in selecting the right model, optimizing process parameters, and ensuring long-term equipment performance. This customer-first approach has helped us build strong relationships across Asia, Europe, Africa, and emerging markets.

As consumers demand healthier, more natural, and more innovative beverage options, the role of advanced homogenization technology becomes increasingly important. Chaoli Homogenizer Factory continues to drive global beverage quality by delivering the precision, efficiency, and reliability that modern producers need. With decades of experience, proven engineering expertise, and a commitment to continuous innovation, Chaoli is helping shape the future of beverage production—one homogenized drop at a time.