How to Choose the Right Homogenizer for Your Business

Homogenizers are critical machines in industries such as dairy, food and beverage, pharmaceuticals, cosmetics, and chemicals. By breaking down particles and dispersing them evenly, homogenizers ensure that products are smooth, stable, and long-lasting. However, with so many types, sizes, and specifications available in the market, choosing the right homogenizer can be a challenging task for businesses. Selecting the wrong equipment can result in inefficiencies, higher costs, and inconsistent product quality. Therefore, it is essential to carefully evaluate your production needs before making a purchase.

At its core, a homogenizer is designed to reduce the size of fat globules or particles and distribute them uniformly in a liquid, creating a stable emulsion. In the dairy industry, this means preventing cream from separating in milk. In pharmaceuticals, it means ensuring precise particle size reduction for drug formulations. Cosmetics rely on homogenizers for consistent textures in creams and lotions, while the chemical industry uses them for dispersing additives and emulsions. Recognizing the function homogenizer in your production process is the first step toward selecting the right one.

Different industries demand different homogenization requirements. For example, dairy producers typically need high-capacity homogenizers capable of handling thousands of liters per hour. Meanwhile, laboratories or pharmaceutical manufacturers often require smaller, bench-top units for precise formulation work. The food and beverage sector may need homogenizers that can handle juices, sauces, and plant-based drinks with varying viscosities. Understanding your application will help narrow down whether you need a small-scale, pilot-scale, or industrial-scale homogenizer.

One of the most important factors in choosing a homogenizer is capacity. The machine you select must match your production volume. Small-scale homogenizers are suitable for research and development, while mid-range models are ideal for pilot plants or small production lines. For large factories, high-pressure homogenizers with high throughput are necessary to meet demand efficiently. Underestimating capacity could cause production delays, while overestimating may lead to unnecessary expenses. Therefore, aligning capacity with your actual production needs is crucial.

Homogenizers are often categorized by the pressure they can achieve. Low-pressure homogenizers are sufficient for some food applications, while high-pressure homogenizers, capable of 20 MPa to 80 MPa, are required for dairy, pharmaceuticals, and cosmetics where fine particle reduction is critical. Higher pressure generally results in smaller particle sizes, smoother textures, and longer product stability. Choosing the right pressure range depends on the product you manufacture and the level of uniformity you require.

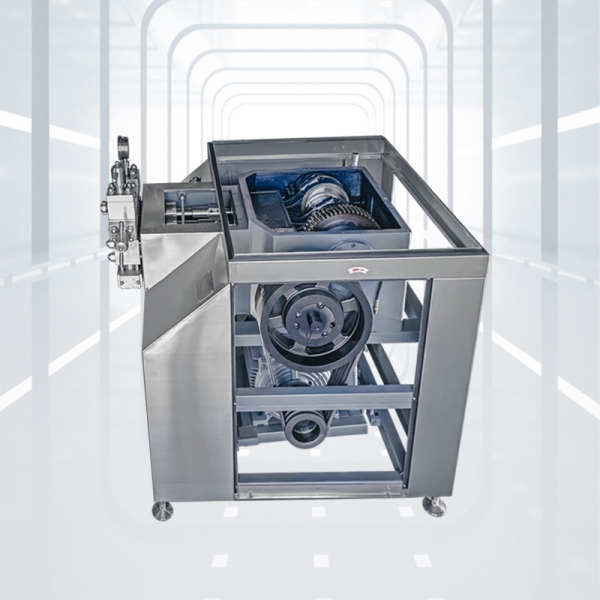

Since homogenizers handle sensitive and often perishable products, the material used in their construction matters. Stainless steel is the preferred material for food, dairy, and pharmaceutical applications because it resists corrosion and is easy to clean. Chemical industries may require special coatings or materials that can withstand acids or aggressive solvents. Beyond material, durability and engineering quality also matter. A well-built homogenizer will reduce maintenance costs and provide consistent performance over time.

Homogenizers are high-performance machines that operate under extreme pressure. Regular maintenance is essential to keep them running smoothly. When choosing a homogenizer, it is important to consider how easy it is to maintain. Can parts be accessed easily for cleaning and replacement? Are spare parts readily available from the manufacturer? A machine that requires complicated maintenance or has long lead times for spare parts could cause costly downtime. Selecting a brand with strong after-sales support ensures long-term reliability.

Food, dairy, and pharmaceutical companies must adhere to strict international safety and quality regulations. Therefore, choosing a homogenizer that complies with standards such as ISO 9001 and CE certification is critical. Compliance not only guarantees product safety but also gives your customers confidence in the quality of your products. Investing in certified equipment also helps businesses meet export requirements and expand into international markets.

While cost is always an important factor, the cheapest option is not always the best. A homogenizer is a long-term investment that directly impacts your product quality and business efficiency. It is wiser to focus on value rather than price alone. Consider factors such as energy efficiency, lifespan, spare parts availability, and after-sales service when calculating the total cost of ownership. Sometimes a slightly more expensive machine with higher efficiency and lower maintenance costs will save more money in the long run.

Choosing the right homogenizer also depends on selecting a reliable manufacturer. Experienced suppliers such as Changzhou Chaoli Homogenizer Factory offer both standard and customized homogenizer solutions. With OEM and ODM capabilities, they can design machines tailored to your specific needs, whether you require a small laboratory homogenizer or a large industrial-scale system. Partnering with an experienced manufacturer ensures technical support, reliable spare parts, and long-term service, reducing the risks associated with equipment breakdowns.

Selecting the right homogenizer for your business is a decision that requires careful consideration of your industry, application, capacity, pressure requirements, and budget. The right equipment ensures better product quality, improved efficiency, and long-term reliability. By working with a trusted manufacturer and focusing on total value rather than just cost, businesses can secure homogenization solutions that meet their needs today and adapt to future demands. Whether in dairy, food, pharmaceuticals, or cosmetics, investing in the right homogenizer is an investment in consistent quality and sustainable growth.