OEM & ODM Solutions for Customized Homogenizers

In today’s highly competitive food, dairy, pharmaceutical, and chemical industries, standard homogenizers often cannot meet the diverse processing requirements of every customer. Different products demand specific capacities, pressure ranges, and design features. This is where OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) solutions play a vital role. Customized homogenizers not only ensure better compatibility with production lines but also enhance efficiency, durability, and product performance. For manufacturers like Changzhou Chaoli Homogenizer Factory, providing tailored solutions has become a cornerstone of serving global clients with precision and reliability.

Understanding OEM & ODM in Homogenizer Manufacturing

OEM and ODM services are often confused, but they serve different purposes. OEM solutions refer to manufacturing homogenizers or parts based on a customer’s design, brand, or specifications. This allows clients to have products that carry their brand identity while relying on the expertise and production capacity of an experienced manufacturer. On the other hand, ODM solutions go one step further by offering complete design and development services. In this case, the manufacturer designs, engineers, and produces customized homogenizers that meet unique processing requirements while incorporating innovative features. Together, these services ensure that customers receive equipment tailored to their exact needs.

Why Customized Homogenizers are Needed

The need for customized homogenizers arises because industries do not all process the same type of materials. For example, dairy producers may require high-capacity homogenizers for milk standardization, while pharmaceutical companies need smaller, laboratory-scale units for precise particle size reduction. Beverage producers may demand equipment with special materials that resist acidity, while cosmetics manufacturers might prioritize homogenizers that deliver stable emulsions with very fine particles. By offering OEM and ODM solutions, manufacturers help customers overcome these challenges by providing equipment that is optimized for their product characteristics, operating environment, and long-term efficiency.

Key Benefits of OEM & ODM Homogenizer Solutions

There are several advantages to investing in customized homogenizers through OEM and ODM partnerships:

Tailored Design – Customers can define their desired capacity, pressure range, and materials of construction, ensuring the homogenizer matches their unique production requirements.

Improved Efficiency – Customized designs reduce energy waste and optimize throughput, lowering operational costs.

Brand Identity – OEM solutions allow companies to market homogenizers under their own brand while benefiting from the expertise of a specialized manufacturer.

Flexibility in Application – Homogenizers can be designed for a wide range of industries, from dairy and beverages to pharmaceuticals, cosmetics, and chemicals.

Long-Term Reliability – ODM designs incorporate advanced R&D to improve durability, ease of maintenance, and compliance with international standards.

These benefits highlight why more companies are moving toward customized solutions rather than relying solely on standard homogenizer models.

Applications Across Different Industries

OEM and ODM homogenizer solutions are valuable because they can be adapted across a wide variety of industries:

Dairy Industry – Customized homogenizers ensure consistent fat distribution in milk and cream, enhancing taste and shelf life.

Beverage Industry – Specialized homogenizers handle juices, sauces, and plant-based drinks with unique viscosity and acidity levels.

Pharmaceutical Industry – Lab-scale homogenizers are customized for nanoparticle production, emulsions, and drug delivery systems.

Cosmetic Industry – Fine emulsification is crucial for lotions, creams, and serums, where uniform texture and stability are essential.

Chemical and Biotechnology Fields – Custom-built homogenizers enable efficient dispersion of chemicals and biological materials, supporting research and large-scale production.

This versatility makes OEM and ODM services essential for industries seeking precision and reliability.

The Process of Developing Customized Homogenizers

The development of OEM and ODM homogenizers usually follows a systematic approach. First, the manufacturer works closely with the client to understand their production requirements, including processing capacity, pressure, materials, and intended applications. Next, the R&D team develops a design concept, often using advanced 3D modeling and simulation tools. Once approved, prototypes are manufactured and tested to ensure performance and reliability. Finally, mass production begins, supported by strict quality control, international certifications, and after-sales service. This process ensures that every customized homogenizer meets customer expectations while complying with industry standards.

Changzhou Chaoli Homogenizer Factory and Custom Solutions

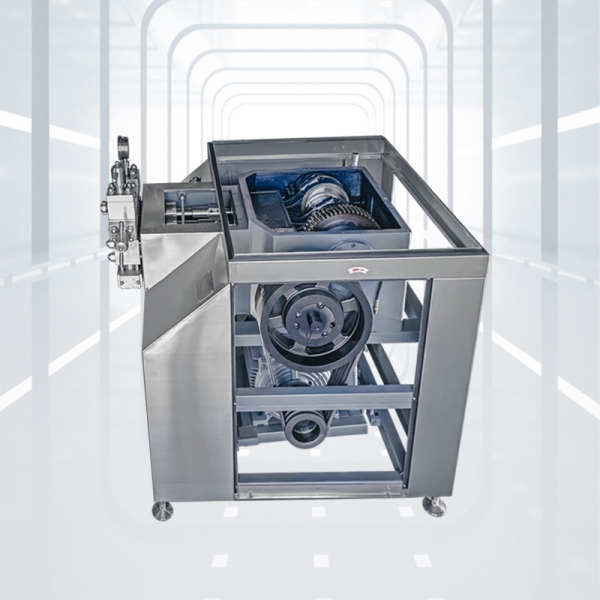

As a leading manufacturer, Changzhou Chaoli Homogenizer Factory has built a reputation for providing reliable OEM and ODM solutions. With decades of experience, the factory combines advanced production equipment, skilled engineering teams, and strict quality management systems to deliver homogenizers that are both efficient and durable. The company offers a wide product range, from small laboratory units to large industrial homogenizers, all of which can be customized to meet specific industry requirements. By working closely with international clients, Chaoli has successfully supplied customized homogenizers across dairy, food, pharmaceutical, and chemical sectors, supporting their growth and innovation.

Future Trends in Customized Homogenizers

As industries continue to evolve, the demand for customized homogenization equipment is expected to grow. Future trends include energy-efficient designs that reduce environmental impact, digital monitoring systems that provide real-time performance data, and automation features that improve consistency and reduce labor requirements. OEM and ODM partnerships will play a critical role in meeting these future demands, enabling manufacturers to deliver solutions that combine innovation with reliability.

Conclusion

In a global marketplace where every industry has unique requirements, OEM and ODM solutions for customized homogenizers are more important than ever. These services allow companies to access equipment designed specifically for their processes, ensuring improved performance, efficiency, and product quality. By partnering with experienced manufacturers like Changzhou Chaoli Homogenizer Factory, businesses can secure reliable and innovative homogenization solutions that strengthen their competitiveness and support long-term success.