The Role of High-Pressure Homogenizers in Modern Food Processing and Why They’re Essential

In today’s fast-paced food industry, quality, consistency, and efficiency are more important than ever. From beverages to dairy products, sauces, and ice creams, the demand for smooth textures, enhanced flavors, and superior product stability is ever-increasing. This is where high-pressure homogenizers come into play—revolutionizing how food is processed to achieve these goals. But what exactly is a high-pressure homogenizer, and why is it so essential in modern food production? Let's explore.

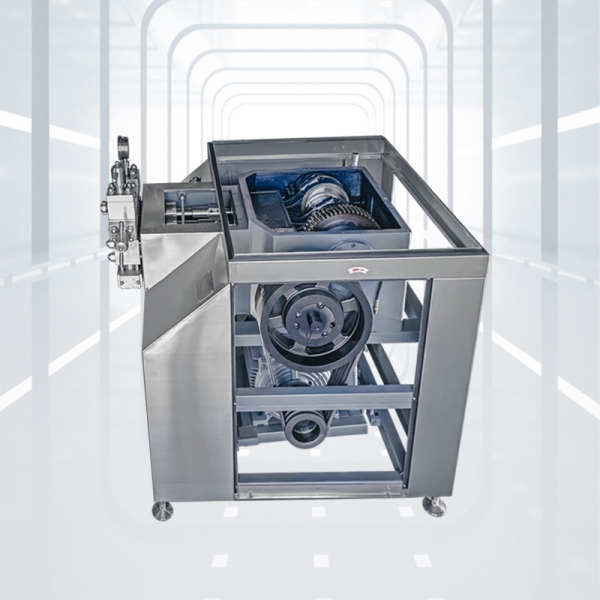

What is a High-Pressure Homogenizer?

A high-pressure homogenizer is a mechanical device that forces a mixture (such as liquid food products) through a narrow valve under extremely high pressure. The purpose is to break down the particles within the mixture into smaller, more uniform sizes. This process improves the texture, consistency, and stability of food products.

At its core, homogenization is all about creating a more uniform and stable product. It works by applying high pressure to break up particles—such as fats, proteins, and fibers—into smaller, more evenly distributed sizes. This results in a smoother, creamier texture and ensures that ingredients stay mixed, preventing separation.

Why High-Pressure Homogenizers Are Essential in Food Processing

1. Improved Texture and Mouthfeel

One of the key reasons food manufacturers rely on high-pressure homogenizers is the ability to create a smoother, more desirable texture. Whether it’s dairy products like milk, cream, or yogurt, or beverages like juices and sauces, the ability to finely homogenize particles allows the product to have a consistent mouthfeel.

For example, milk homogenization prevents cream from separating and floating to the top. In juices, it ensures that pulp and water stay evenly distributed, providing a better drinking experience.

2. Enhanced Flavor Release and Stability

Homogenization plays a vital role in flavor enhancement. When food particles are broken down into smaller, more consistent sizes, the surface area increases, allowing flavors to release more effectively. This is particularly important in the production of beverages and sauces, where flavor consistency across large batches is critical.

Additionally, high-pressure homogenizers help stabilize emulsions (mixtures of oil and water) in products like dressings, mayonnaise, and sauces, ensuring that the product remains uniform over time and does not separate.

3. Longer Shelf Life and Stability

One of the most significant benefits of high-pressure homogenization is its ability to extend the shelf life of food products. By breaking down particles and creating a finer emulsion, the product becomes less prone to spoilage. Homogenized milk, for instance, stays fresher longer than non-homogenized milk due to its reduced fat globule size and better integration of fat and water.

This process also improves product stability under varying conditions, such as temperature changes or long storage periods, ensuring that the product retains its quality throughout its shelf life.

4. Improved Nutritional Quality

High-pressure homogenization allows food manufacturers to optimize the nutritional profile of their products. For instance, it can help incorporate nutrients like vitamins, minerals, and proteins more efficiently into a product. In dairy, this process can enhance the bioavailability of beneficial components such as calcium, making them easier for the body to absorb.

Moreover, high-pressure homogenization is a non-thermal process, meaning it preserves the nutrients and sensitive compounds in foods better than traditional heating methods, which can degrade vitamins and other essential nutrients.

5. Better Product Consistency and Quality Control

Consistency is the cornerstone of modern food production. High-pressure homogenizers ensure that every batch of product is uniformly processed, leading to consistent results. This not only helps maintain the desired flavor, texture, and appearance but also reduces product variability, a critical aspect for large-scale food manufacturers.

For large brands that produce millions of units, consistency is a non-negotiable factor. Homogenizers enable them to maintain tight control over every product, ensuring that consumers receive the same quality every time they purchase a product.

Applications of High-Pressure Homogenizers in Food Processing

1. Dairy Industry

The dairy industry was one of the first sectors to adopt high-pressure homogenization on a large scale. Homogenizers are used in the production of milk, yogurt, cream, butter, and ice cream. For example, homogenized milk is smoother and creamier, while ice cream benefits from a smoother texture and better air incorporation.

2. Beverages and Juices

Homogenization is crucial for beverages, especially in the production of fruit juices, smoothies, and plant-based milk. It ensures that pulp, flavoring, and other ingredients remain evenly distributed. High-pressure homogenization also helps in stabilizing the emulsions in milk-based drinks like flavored milks and smoothies, preventing separation.

3. Sauces, Dressings, and Mayonnaise

High-pressure homogenizers are widely used in the production of sauces and condiments, such as mayonnaise and salad dressings. These products often contain emulsions that need to remain stable. Homogenization ensures that the oil and water phases are evenly dispersed, giving these products their smooth, creamy texture and preventing the separation of ingredients over time.

- Processed Foods and Plant-Based Alternatives

Homogenizers also play a significant role in the production of plant-based food alternatives, like plant-based milk (soy, almond, oat, etc.). These products require fine particle sizes to mimic the creamy texture of dairy milk. High-pressure homogenization ensures that plant proteins and fats are properly emulsified, resulting in better texture and stability.

Conclusion

High-pressure homogenizers are an integral part of modern food processing, playing a crucial role in enhancing the quality, consistency, and stability of food products. From improving texture and flavor to extending shelf life and preserving nutritional quality, these machines are indispensable in the production of dairy, beverages, sauces, and more.

As food manufacturers continue to seek innovative solutions for improving product quality and meeting consumer demands, high-pressure homogenizers will remain at the forefront of the industry. Whether you’re producing beverages, dairy products, or condiments, Chaoli Homogenizers offer the technology you need to ensure top-notch quality in every batch.