Which Chaoli Homogenizer Fits Your Specific Industry Needs?

Choosing the right homogenizer is a critical decision for manufacturers who depend on consistency, stability, and efficiency in their production processes. Different industries place different demands on homogenization, from precise particle size reduction to high flow capacity and long-term durability. With decades of manufacturing experience and a comprehensive product range, Chaoli Homogenizer Factory offers solutions tailored to meet diverse industry requirements. Understanding your application is the first step toward selecting the most suitable Chaoli homogenizer. For the food and beverage industry, smooth texture, uniform dispersion, and stable emulsions are essential. Products such as milk, yogurt, juices, sauces, and plant-based beverages require consistent particle size reduction to prevent separation and improve mouthfeel. Chaoli models like the 3011 and 3015 are well-suited for small to medium-scale food processing, pilot production, and specialty product lines. They provide stable pressure and sufficient flow while maintaining gentle processing to preserve flavor and nutritional value.

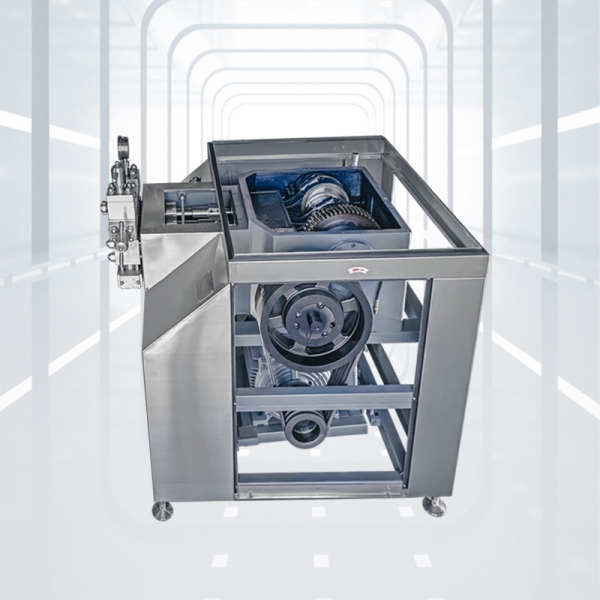

In dairy and beverage factories with higher output demands, larger-capacity homogenizers become necessary. The 3030 and 3045 models are designed to handle increased flow rates without sacrificing homogenization quality. These machines are ideal for continuous production environments where consistency across large batches is critical. Their robust construction and reliable pressure performance make them a dependable choice for producers aiming to scale operations while maintaining product quality. For the biologics and pharmaceutical engineering sectors, precision and control are paramount. Applications such as cell disruption, protein extraction, nano-suspensions, and injectable formulations require extremely uniform particle sizes and stable operating conditions. Chaoli’s 3090 and 4110 homogenizers are engineered for high-pressure, high-precision processing, making them suitable for demanding pharmaceutical and biologics applications. Their ability to deliver repeatable results supports strict regulatory and quality requirements.

The cosmetics and personal care industry also benefits from advanced homogenization technology. Creams, lotions, serums, and emulsions require smooth textures and long-term stability to meet consumer expectations. Chaoli homogenizers ensure fine emulsification and consistent dispersion of active ingredients, helping cosmetic manufacturers achieve premium product quality. Medium to high-capacity models are often preferred to balance precision with efficient production output. For nano-material and advanced material applications, accurate control over particle size and distribution is essential. Whether producing nano-emulsions, dispersions, or functional materials, Chaoli homogenizers provide the mechanical force needed to achieve nanoscale results. High-pressure models offer the stability and power required to support research, pilot testing, and industrial-scale production in this highly technical field.

Ultimately, the right Chaoli homogenizer depends on your industry, production volume, and processing objectives. From compact models for pilot and small-scale operations to high-capacity systems for continuous industrial production, Chaoli offers a flexible product lineup supported by expert technical guidance. By aligning the right equipment with your specific application, Chaoli Homogenizer Factory helps you achieve consistent quality, efficient production, and long-term operational success.