Why High-Pressure Homogenization Beats Traditional Mixing Methods

In many industries, from food and cosmetics to pharmaceuticals and chemical processing, efficient mixing is the foundation of product quality. While traditional methods such as stirring, blending, and milling have been widely used, growing production demands and stricter quality expectations have highlighted their limitations. Today, high-pressure homogenization has emerged as a superior technique, delivering the uniformity, stability, and precision that modern formulations require. Chaoli Homogenizer Factory has been at the forefront of this advancement, providing technology that outperforms older mixing approaches in every critical aspect. Traditional mixing methods rely primarily on mechanical agitation, which provides only surface-level blending. These processes can disperse ingredients but struggle to break down particles evenly. As a result, mixtures often contain large droplets or clusters that lead to inconsistency, poor texture, and separation over time. High-pressure homogenization solves this problem by applying intense mechanical forces to reduce particle size, creating stable structures that cannot be achieved through simple stirring or agitation.

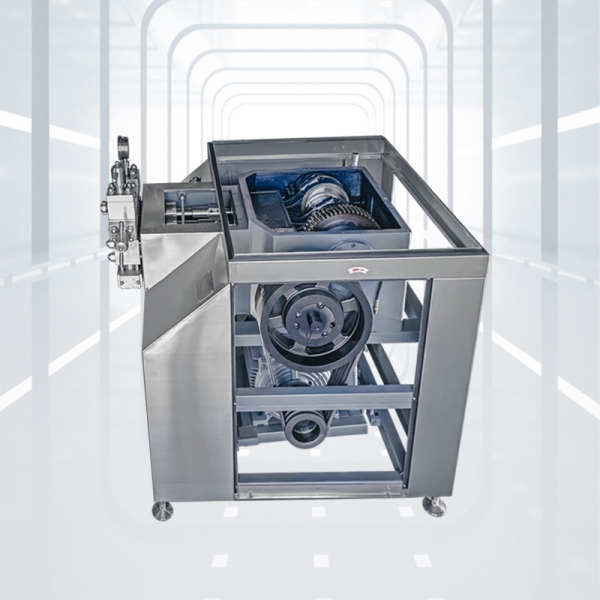

The key advantage of homogenization lies in its ability to dramatically reduce particle size and ensure uniform distribution. When material is forced through a narrow valve at extremely high pressure, it experiences turbulence, shear force, and cavitation. These forces shatter droplets and particles into micron or even nano-sized units, creating fine emulsions or dispersions with exceptional stability. No traditional mixer can deliver this level of refinement, especially when processing highly viscous or multi-phase products. Product stability is another area where homogenization surpasses conventional methods. Poorly dispersed ingredients tend to separate over time, reducing shelf life and affecting product appearance and performance. High-pressure homogenization creates formulations that resist creaming, settling, coagulation, and phase separation. In industries like dairy, cosmetics, biologics, and pharmaceuticals, this stability directly translates into better customer satisfaction and lower waste.

Efficiency also sets homogenization apart. Traditional mixing often requires long processing cycles, repeated passes, or multiple secondary steps to reach acceptable results. Homogenizers complete particle size reduction in a single flow, drastically reducing processing time. Chaoli homogenizers provide high flow rates, stable pressure, and reliable performance, helping manufacturers speed up production and increase output without compromising quality. For specialized applications—such as plant-based beverages, nano-materials, cell disruption, or injectable formulations—traditional mixers are simply insufficient. These products require extremely fine dispersion and controlled particle size to achieve the desired function. Homogenization is uniquely suited for these demanding tasks, ensuring reliable performance across a broad range of industries.

Finally, high-pressure homogenization delivers long-term economic benefits. Although homogenizers require more engineering precision than standard mixers, they reduce operational costs by increasing yield, minimizing batch failures, and lowering additive requirements. Because ingredients blend more effectively, manufacturers often use less stabilizer, emulsifier, and thickener—saving money while improving product quality. From texture and flavor to stability and performance, high-pressure homogenization consistently outperforms traditional mixing methods. With advanced equipment designed for durability, efficiency, and precision, Chaoli Homogenizer Factory provides manufacturers with the tools they need to stay ahead in competitive markets. For companies committed to quality, innovation, and long-term value, homogenization is not just an upgrade—it is an essential step toward production excellence.