Why Homogenizers are Critical for Cell Disruption in Biotech Research

Biotechnology is one of the fastest-growing scientific fields, driving innovation in pharmaceuticals, healthcare, food technology, and bioengineering. A crucial step in many biotech processes is cell disruption, which involves breaking open cells to release valuable intracellular components such as proteins, DNA, enzymes, or other biomolecules. Among the various methods available, homogenization stands out as one of the most efficient and reliable techniques. Homogenizers have become indispensable in biotech research because they ensure consistent results, scalability, and the preservation of sensitive biomolecules during extraction.

Cell disruption is necessary whenever researchers or manufacturers need to access the contents of microbial, plant, or animal cells. For example, recombinant protein production often involves cultivating bacteria or yeast, followed by extraction of the target protein. Similarly, vaccines, enzymes, and other biological products require efficient recovery from cells. The challenge lies in breaking the cell wall or membrane without damaging the valuable molecules inside. Inadequate disruption can lead to low yields, while harsh methods may destroy fragile proteins and enzymes. This is why selecting the right technology is vital.

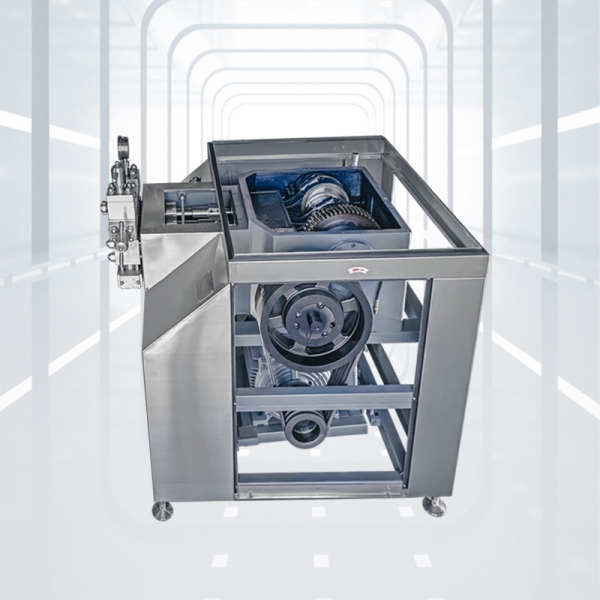

Homogenizers work by forcing a cell suspension through a narrow valve at high pressure. The sudden pressure drop, combined with intense shear forces and turbulence, causes the cells to rupture. Unlike mechanical grinding or chemical lysis, homogenization does not require harsh chemicals or enzymes, making it cleaner and more cost-effective. The process can be carefully controlled to achieve the desired level of disruption, whether breaking tough bacterial cell walls or gently rupturing mammalian cells. This flexibility makes homogenizers suitable for a wide range of applications in biotechnology.

Several techniques exist for cell disruption, including sonication, bead milling, enzymatic lysis, and chemical treatment. However, homogenizers offer key advantages that make them preferable in many biotech laboratories and production facilities:

Scalability – Homogenizers are available in bench-top models for research and large-scale units for industrial production, ensuring smooth transition from lab to factory.

Consistency – The process produces uniform and repeatable results, which is critical for research reproducibility and product quality.

Preservation of Biomolecules – Unlike harsh chemical methods, homogenization minimizes damage to sensitive proteins, enzymes, and nucleic acids.

Reduced Contamination Risk – The closed system design of homogenizers reduces the risk of introducing contaminants compared to open mechanical disruption methods.

Time Efficiency – High-pressure homogenization processes large volumes quickly, making it ideal for large-scale biotech production.

Homogenizers are widely used in biotechnology for a variety of purposes:

Protein Extraction – Homogenization is one of the most effective ways to release recombinant proteins from bacterial or yeast cells.

Vaccine Development – Cell disruption is essential for recovering antigens, viral particles, or adjuvants used in vaccines.

Enzyme Production – Industrial enzymes such as amylases, proteases, or cellulases are extracted from microbial cells through homogenization.

Genomics and Proteomics – Researchers use homogenizers to prepare cell lysates for DNA, RNA, and protein analysis.

Biopharmaceuticals – Large-scale homogenization enables consistent production of therapeutic molecules with high purity and activity.

These applications demonstrate why homogenizers are critical to both laboratory research and industrial-scale biotechnology.

One of the greatest benefits of homogenizers in biotech research is their ability to maximize yield while preserving product integrity. Because homogenization does not rely on chemical additives, the risk of contaminating the sample is minimized. At the same time, the ability to finely control pressure and flow conditions means researchers can optimize the balance between complete disruption and protection of delicate biomolecules. This ensures that the extracted material is not only abundant but also functionally active, which is crucial for research accuracy and pharmaceutical effectiveness.

While some may consider homogenization an energy-intensive process, modern homogenizers are increasingly designed with energy-efficient systems that reduce operational costs. Compared to alternative cell disruption methods, homogenizers offer better throughput and lower processing time, saving both energy and labor. Additionally, because the process does not require expensive chemicals or enzymes, overall costs for cell disruption are significantly reduced, especially at large scales. This makes homogenization both a scientifically and economically attractive choice for biotech research facilities.

Not all homogenizers are identical, and biotechnology often requires customized solutions. Through OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) services, manufacturers can design homogenizers tailored for specific biotech processes. For example, a lab studying microbial enzymes may require small-scale bench-top homogenizers, while a biopharmaceutical company may need high-pressure, large-capacity units. Manufacturers like Changzhou Chaoli Homogenizer Factory offer customization to ensure that researchers and industries can achieve maximum efficiency and reliability in their cell disruption processes.

The role of homogenizers in biotech research is expected to grow even more significant in the future. With advances in genetic engineering, nanotechnology, and personalized medicine, the demand for precise, scalable, and reliable cell disruption methods will continue to increase. Future homogenizers will likely integrate smart sensors, automation, and real-time monitoring to further improve efficiency and reproducibility. As sustainability becomes a priority, energy-efficient designs will also play a key role in making biotech processes more environmentally friendly.

Cell disruption is at the heart of many biotechnology processes, from protein production to vaccine development. Among the available methods, homogenization has proven to be one of the most effective, scalable, and reliable techniques. By offering consistent results, preserving delicate biomolecules, and ensuring cost-efficiency, homogenizers have become indispensable tools in biotech research and industrial production. With ongoing technological advancements and customization options, homogenizers will continue to play a central role in unlocking the full potential of biotechnology.