Source:Changzhou Chaoli Homogenizer Factory Release time:2023-09-05 16:26:18 Author:511

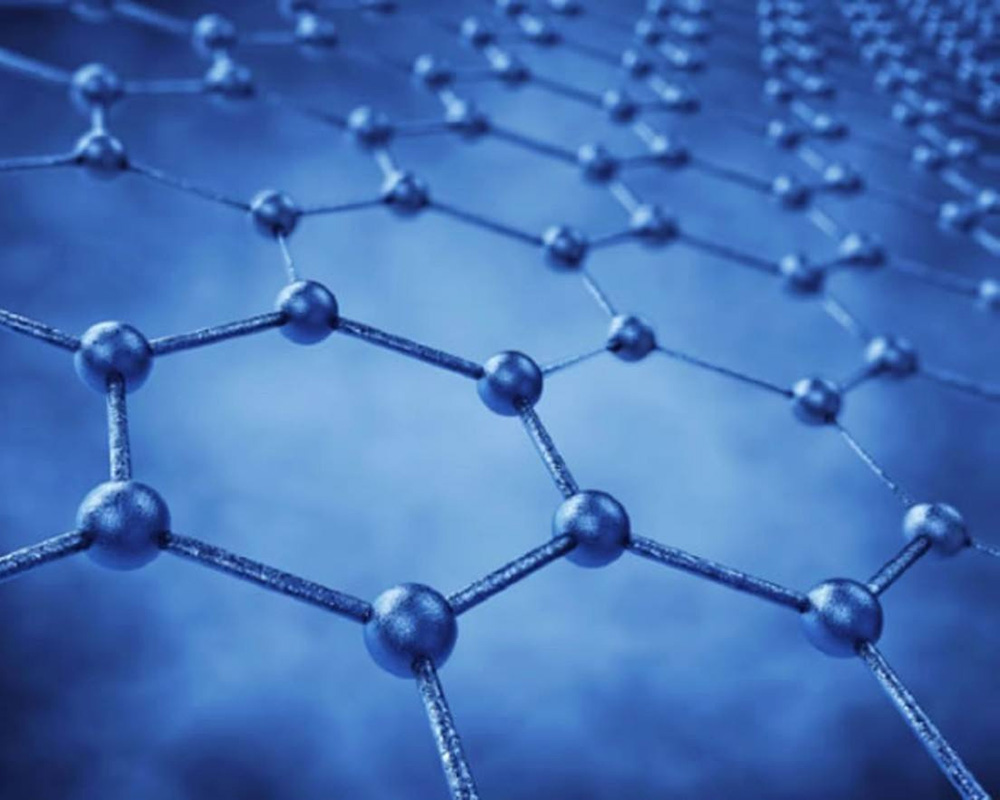

Graphene is a two-dimensional material composed of carbon atoms with sp2 hybrid orbitals forming a hexagonal honeycomb lattice planar film with only one carbon atom thickness. Graphene is currently the thinnest but hardest nanomaterial in the world, almost completely transparent; its thermal conductivity is higher than carbon nanotubes and diamond, and its electron mobility exceeds 15,000cm2/Vs at room temperature, which is higher than carbon nanotubes or silicon crystals. The resistivity is lower than that of copper or silver, and it is the material with the smallest resistivity in the world. The excellent physical and structural properties of graphene materials show extraordinary potential application in many fields such as electronics, sensing, coatings and optoelectronic devices.

However, graphene materials are difficult to disperse in other base matrices, which is a difficulty that restricts its large-scale application. It requires an equipment that can loosen and disperse the particles well before it can exert its excellent properties. High-pressure homogenization, as the most advanced wet high-pressure dispersion technology today, provides a very good nano-homogenization solution to the above-mentioned problems of graphene materials, and can solve the problems of particle size refinement and uniform dispersion.

The principle of the high-pressure homogenizer is: use a plunger pump to pump the sample into the equipment module. The liquid will pass through a slit formed by a homogenization valve assembly under high compression, and produce three effects. The first is the shearing effect occurs when the sample passes through the sharp edge of the homogenization valve. The second type is the impact effect caused by violent impact on the homogenization valve ring at an extremely fast speed. The third type is the instant when the sample moves from the high pressure area to the low pressure area. Pressure release, also known as the blast effect. Without the high-pressure homogenization process, graphene will agglomerate and precipitate. However, after the high-pressure homogenization process, the graphene sheets become thinner and the corresponding solution can be stably dispersed. Since no reducing agent is used, the graphene prepared is non-toxic and harmless, and no surfactant is added, and the conductivity of graphene is also greatly improved.

For graphene, which is not very hard but needs to reach a stable state, it needs a more uniform particle size, which is more conducive to the stability of the system. The homogenizer equipment works in a continuous flow and can process all samples with the same conditions which is very important to control the conditions of experiments and production.