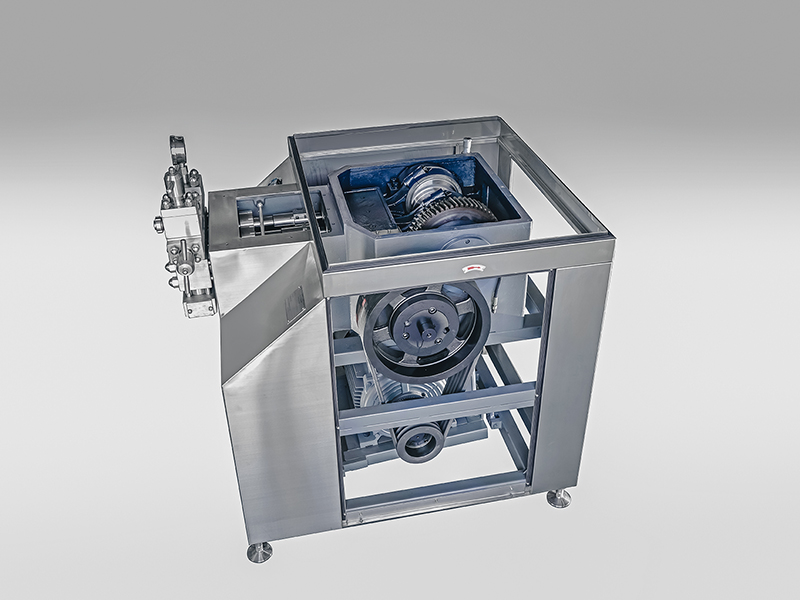

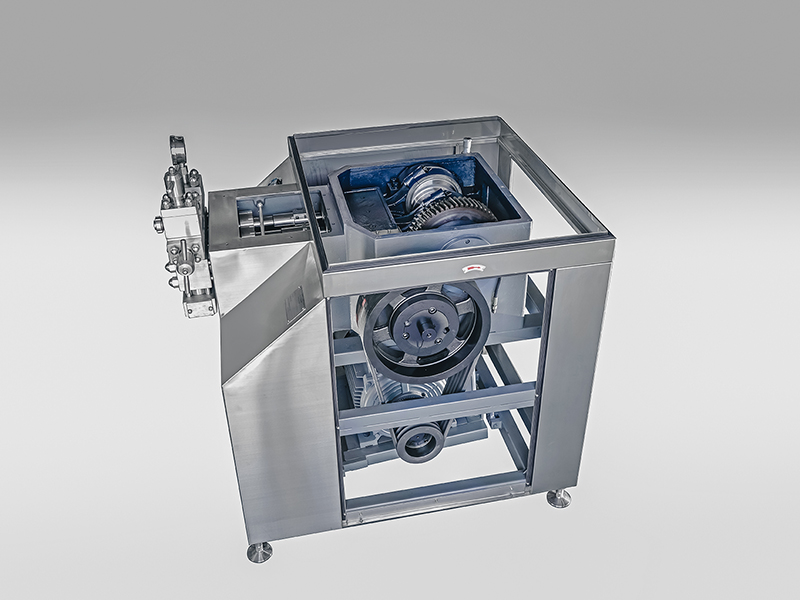

High-pressure homogenizer is a kind of equipment that uses high pressure, high speed and high shear force to process samples. It is widely used in biomedicine, food, chemical and other fields.

The high pressure homogenizer consists of the following parts:

1. the host

The main part of the high-pressure homogenizer is the host, which is composed of a pressure generator, a homogenizer, a water cooling system, and a pressure sensor. The function of the main machine is to provide high pressure, high speed, high shear force and other forces according to the different characteristics and processing requirements of the samples, so as to disperse, decompose and dissolve the samples.

2. Homogenizer

The homogenizer is one of the most important components in the high-pressure homogenizer. It is responsible for maximizing the contact area between the sample and the homogeneous medium. Uniform processing at high speed and high pressure. When designing a homogenizer, the characteristics and processing requirements of the sample must be considered, and homogenizers of different shapes and materials must be selected to achieve the best processing effect.

3. pressure generator

The pressure generator is the part that controls the high pressure in the high-pressure homogenizer, and it usually consists of a high-pressure pump, connecting pipelines, pressure sensors, etc. The pressure generator plays a crucial role in the processing effect of the whole equipment, because the homogenizer can only effectively process the sample when the equipment provides a high enough pressure.

4. water cooling system

A large amount of energy generated in the high-pressure homogenizer will cause the temperature to rise. In order to avoid overheating of the equipment and protect the stability and life of the equipment, a water cooling system needs to be installed to circulate and cool the water in the homogenizer and pressure generator to reduce The temperature of the device.

5. Control System

The control system in the high-pressure homogenizer includes temperature controllers, pressure controllers, timers and other parts, which work together to ensure the safety, stability and efficiency of the equipment. Through the control system, the processing of samples is controlled within a reasonable range to avoid accidents during processing.

Although the composition of the high-pressure homogenizer is diverse, it generally has the above-mentioned parts, and there is a certain correlation and logic between the parts. When performing high-pressure homogeneous treatment, it is necessary to fully consider the nature of the sample, processing requirements, and equipment characteristics and parameters in order to achieve the best processing effect.