Source:Changzhou Chaoli Homogenizer Factory Release time:2023-08-23 08:58:31 Author:2495

1. The high-pressure homogenizer uses a high-pressure reciprocating pump (for more information on the principle of the reciprocating pump, please click here) as the power transmission and material delivery mechanism to deliver the material to the working valve (first-level homogenizing valve and second-level emulsification valve). When the material to be processed passes through the working valve, strong shearing, impact and cavitation effects are generated under high pressure, so that the liquid material or the solid particle with the liquid as the carrier is ultrafine.

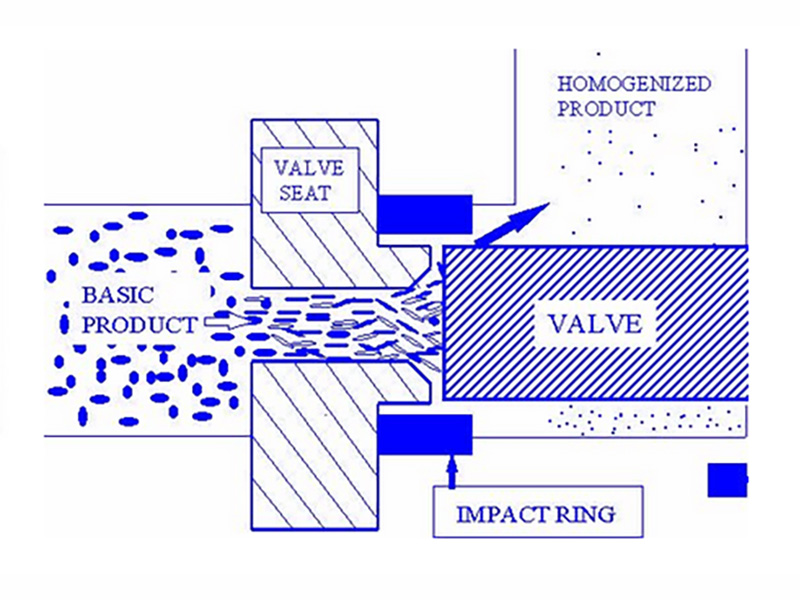

2. Schematic diagram of the principle and a brief introduction to the principle of particle refinement

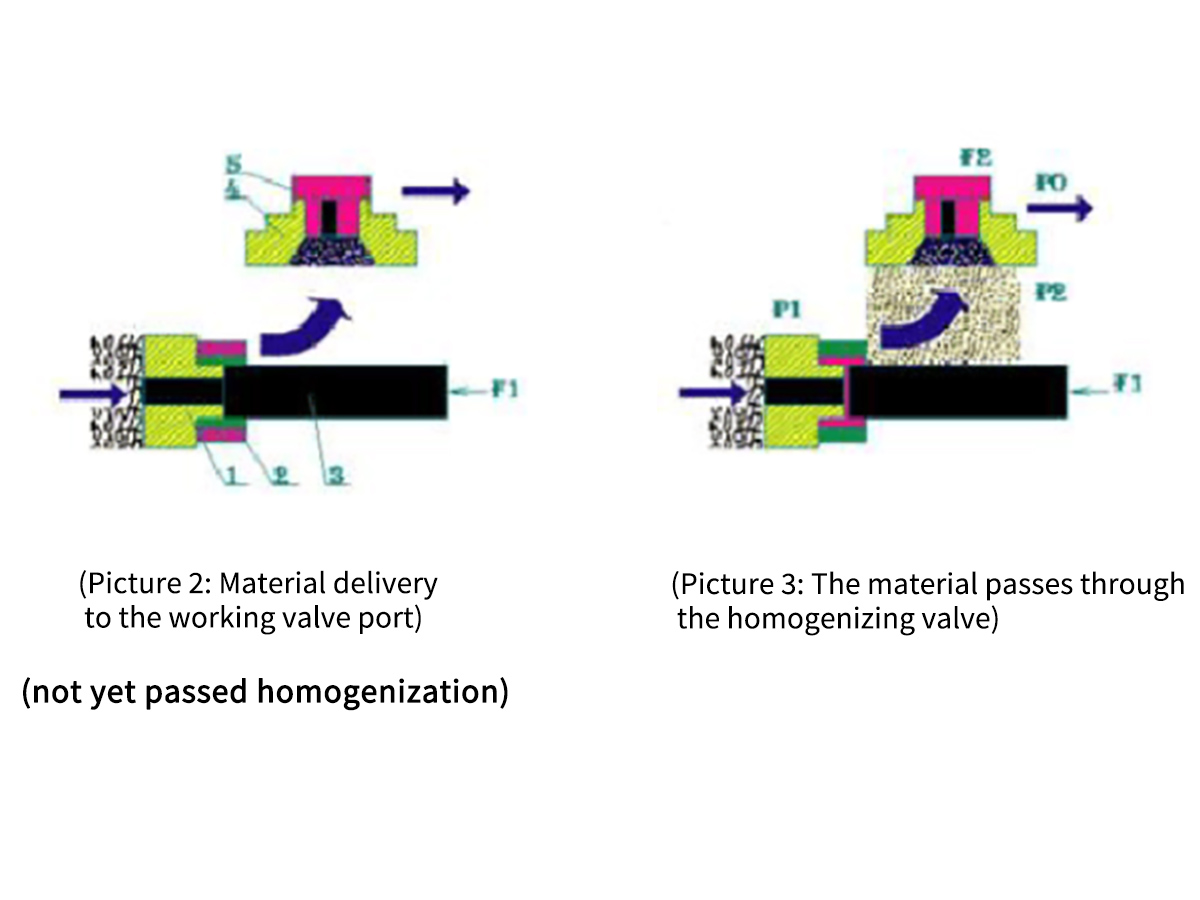

3. As shown in Figure 2,

When the material has not passed through the working valve, the valve core and valve seat of the first-stage homogenizing valve and the second-stage emulsification valve are tightly fitted together under the action of forces F1 and F2. When the material passes through the working valve (as shown in Figure 3), the valve core and the valve seat are forced to open a slit by the material, and at the same time, the pressure P1 and P2 are respectively generated to balance the forces F1 and F2. When the material passes through the first-stage homogeneous valve (serial number 1, 2, 3), the pressure suddenly drops from P1 to P2, and with the sudden release of the pressure energy, the valve core, valve seat and impact ring are formed. A strong cavitation effect similar to an explosion effect is generated in a small area of the valve, accompanied by the shearing effect of the material passing through the slit between the valve core and the valve seat and the high-speed impact effect generated by the collision with the impact ring, such a strong comprehensive effect , so that the particles are ultra-fine. Generally speaking, the pressure of P2 (that is, the emulsification pressure) is adjusted very low, and the function of the secondary emulsification valve is mainly to make the finer particles distribute more evenly. According to the information of Gaulin Company in the United States, in most cases, the ideal effect can be obtained by using only one-stage homogenizing valve.

3. Compared with centrifugal dispersing and emulsifying equipment (such as colloid mill, high-shear mixing emulsifying machine, etc.), the characteristics of high-pressure homogenizer are:

1) The refinement effect is stronger. This is because the spool and the valve seat of the working valve are in close contact at the initial position, but a slit is forced out by the material liquid during work; Rotating without generating too much heat, there must be a large gap (compared to the homogenizing valve); at the same time, because the transmission mechanism of the homogenizer is a positive displacement reciprocating pump, theoretically speaking, the homogenizing pressure can be unlimited. The higher the pressure, the better the thinning effect.

2) The refinement function of the homogenizer mainly utilizes the interaction between materials, so the calorific value of the materials is small, so the performance of the materials can be kept basically unchanged.

3) The homogenizer can convey the material quantitatively, because it relies on the reciprocating pump to feed the material.

4) The homogenizer consumes a lot of energy.

5) The homogenizer is more vulnerable, and the maintenance workload is larger, especially in the case of high pressure.

6) The homogenizer is not suitable for the case of high viscosity.